Materials

Ultra-high pressure waterjet technology continues to be the fastest growing major machine tool process in the world. Waterjet Cutting, Inc. has embraced this technology and can provide full service cutting capabilities to our customers regardless of the job size, material or quantity needed.

We offer waterjet cutting with or without abrasive and can recommend the best method to use for your job. Waterjet Cutting, Inc. strives to meet your company’s fluctuating time frames and ever-changing demands.

Our motto, “We will do what it takes to get your job done”, is taken very seriously at Waterjet Cutting Inc. The following are examples of the many materials that we have cut. We are in no way limited to just these materials and would enjoy discussing your project’s requirements.

Ceramics – Tile

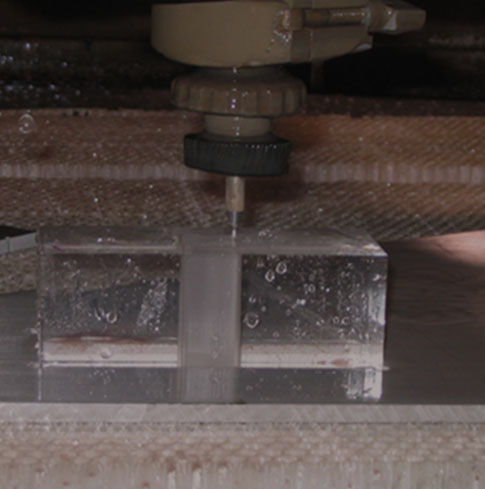

Glass

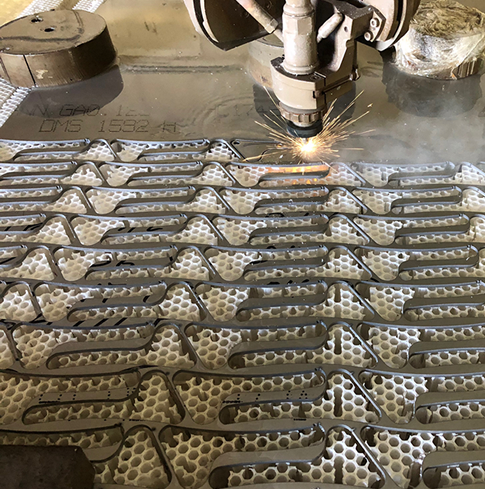

Metal

Rubber/Plastic

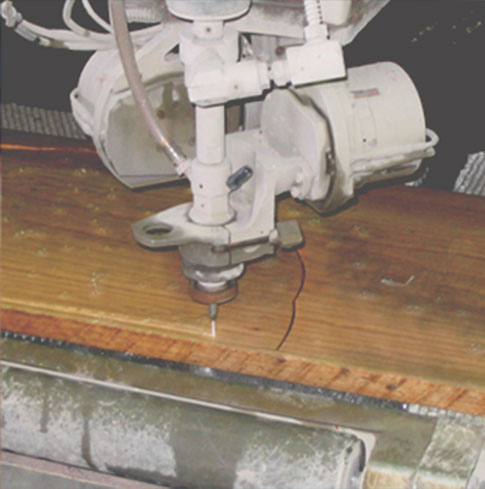

Stone

Wood

What We can and cannot cut

The waterjet cutting process has the ability to cut most material including heat-sensitive, delicate or very hard materials.

However, one of the materials that cannot be cut with a waterjet is tempered glass, the glass will shatter. We also do not cut material that is labeled as hazardous. Waterjet cutting has shown that it can accomplish intricate cuts and complex shapes. The kerf width of the cut is small and that advantage, along with our programming knowledge and techniques, will allow us to produce parts with very little material waste.

How it works

The control system of the waterjet machine is the software program, along with the operator interface and your electronically transmitted drawing.

Using the specialized software program and the waterjet, your project ideas can become a reality. Our machines can handle a flat stock material size of up to 6.5’ x 13’. We believe that with our 4 machines, we are capable of meeting all of your cutting needs and time constraints.

Costs

The cost of the project is determined by the project set-up, material type, programming and machine cycle-time. Our in-house technical experts can assist you and answer any questions you may have on the setup of your job and our waterjet cutting application. We can program your job as part of the project fee or you can supply the CAD drawings. Shipping of your manufactured parts directly to you or your customers can also be added to any quote.

Waterjet Cutting

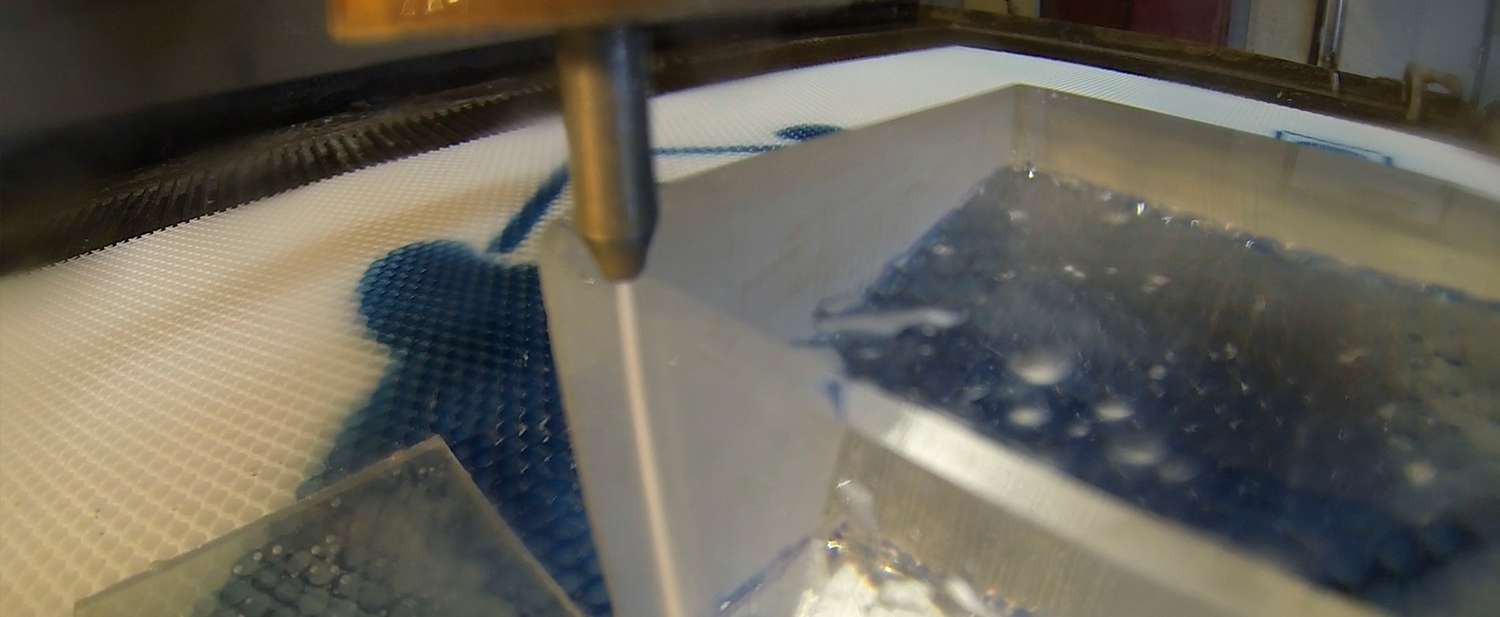

We offer water-only cutting, no abrasives are used in the cutting process. This type of waterjet cutting is used to cut soft material like gaskets, foam, plastic, paper, disposable diapers, insulation, cement board, automotive interiors, carpets, and food.

Our abrasive cutting is recommended for hard materials and is a more powerful and aggressive form of waterjet cutting. The waterjet stream contains abrasive particles (garnet, etc.) not just water.

Waterjet Cutting, Inc. realizes that every customer has unique aspects to their job and we strive to help in any way possible to accomplish your project goals.